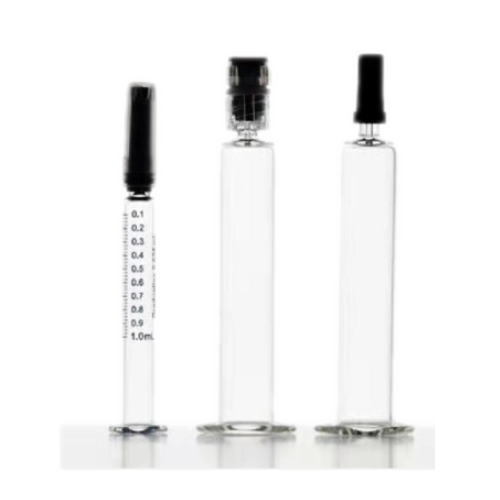

Laser drilling

The main positive sample preparation technology used - laser drilling technology - is recognized by the US FDA and the most authoritative positive sample preparation technology cited by USP1207.

The advantage of laser drilling technology compared to other positive sample preparation methods is that the geometric shape and internal gas flow behavior of the leakage hole are closest to real defects, and the leakage channel generated by laser drilling is an irregular and tortuous channel, which is very close to real defects.

Each leak is equipped with a leak verification certificate to ensure that the size of the leak is traceable. Currently, laser drilling technology has a minimum hole diameter of approximately 1um on hard glass or plastic materials, and smaller holes can easily be blocked by environmental dust and impurities.

| Product Name | CCIT positive sample |

| Method advantages | Laser drilling is a form of leakage that does not introduce other impurities and is close to real leakage. |

| Compliance | The aperture leakage rate meets the requirements of USP1207 and the "Technical Guidelines for Sealing Research of Chemical Injection Packaging Systems (Trial)". |

| Aperture range | one μ M~50.0 μ M |

| Punching position | Bottle body, bottom, bottleneck, etc |

| Suitable for packaging materials | Vials, ampoules, molded bottles, infusion bags, plastic bags, pre filled needles, cartridge bottles, upright bags, pre filled seals, etc |