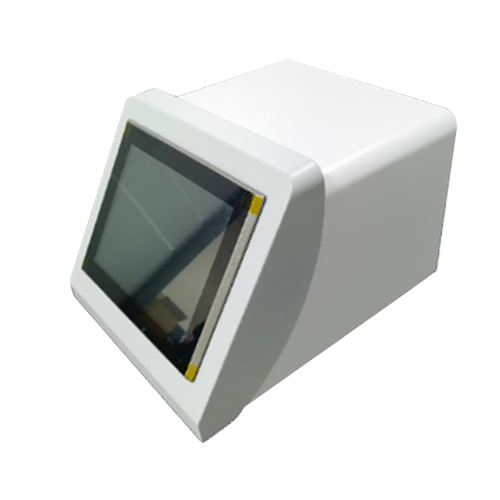

Leak Test Systems

Model: RC-010

The RC-010 packaging sealing tester can be used in the pharmaceutical industry for rigid packaging containers such as penicillin bottles, pre filled syringes, ampoules, infusion bottles, or flexible packaging (such as infusion soft bags) for filling powders, freeze-drying, and pharmaceutical liquids. The Chinese and English operating system is convenient, simple, fast in testing, reproducible in testing results, and highly sensitive. The testing process is completely non-destructive to the packaging and does not require sample preparation. It can be used for research and development, QC, and production release.

Technology:

The RC-010 packaging sealing tester is connected to a testing chamber designed according to the size of the packaging material, and the testing chamber is vacuumed. The high-resolution absolute pressure sensor is used to monitor and test the vacuum degree of the cavity. The mathematical model records and compares the vacuum degree data to calculate the leakage, and the equipment can detect large and small leaks. The testing cycle takes a very short time, the results are non subjective, and the product is non-destructive.

Features:

Detection sensitivity 1 micron

Complies with FDA, EU, China CDE regulations, ASTM testing standards

Fast testing speed

Widely applicable, suitable for products such as powder injection, freeze-drying, and water injection, as well as flexible packaging such as rigid packaging and infusion bags

Non destructive, non subjective

Determined and quantitative testing methods

Comprehensive upgrade of cavity to improve accuracy